The use of real-time automated process monitoring and control can improve quality, yield, reliability and safety in applications such as yogurt fermentation, industrial process control, bio-reactor monitoring, Process Analytical Technology and beer fermentation process quality control.

DUV Fluorescence Spectroscopy and Raman Spectroscopy are well developed techniques that allow on-line measurements of both product and substrate concentrations as well as the identification of particular process states.

Traditionally, off-line tests such as HPLC are used to monitor process parameters. However, the time delay between sample taking and test results is a major disadvantage.

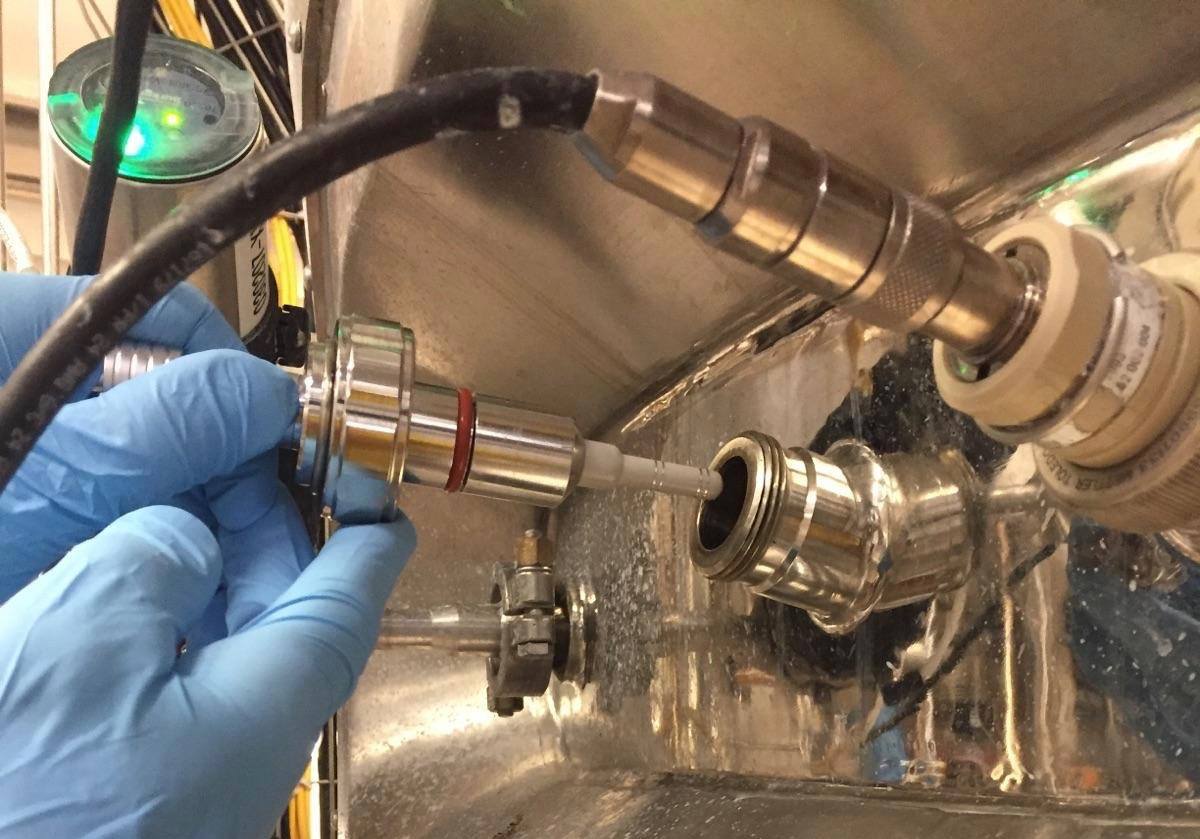

Photon Systems DUV Fluorescence and Raman Spectroscopy instruments enable real-time, non-invasive and highly sensitive monitoring of process reactions.

Key Features

Real Time

Deep UV autofluorescence and Raman monitors provide real time process information. No taking samples to the lab and waiting.

Downloads

Yogurt Fermentation Process Control

Real time deep UV fluorescence instruments allow continuous monitoring of yogurt fermentation process which improves manufacturing yield and quality

Process Analytical Technology

Modern process control engineering and manufacturing achieves higher quality and reduced costs through the use of on-line process monitoring.

TraC

With a compact hand-held form factor, deep UV excitation, and up to 4 customizable fluorescence channels, the TraC is designed for highly selective and sensitive real-time optical scanning.

DUV Raman PL 200

A fully integrated lab model deep UV resonance Raman and photoluminescence spectrometer with microscopic imaging.

Get In Touch

Keep informed about the latest deep UV developments at Photon Systems by joining our mailing list.

ADDRESS

1512 Industrial Park St. Covina, CA 91722-3417

PHONE

626 967-6431