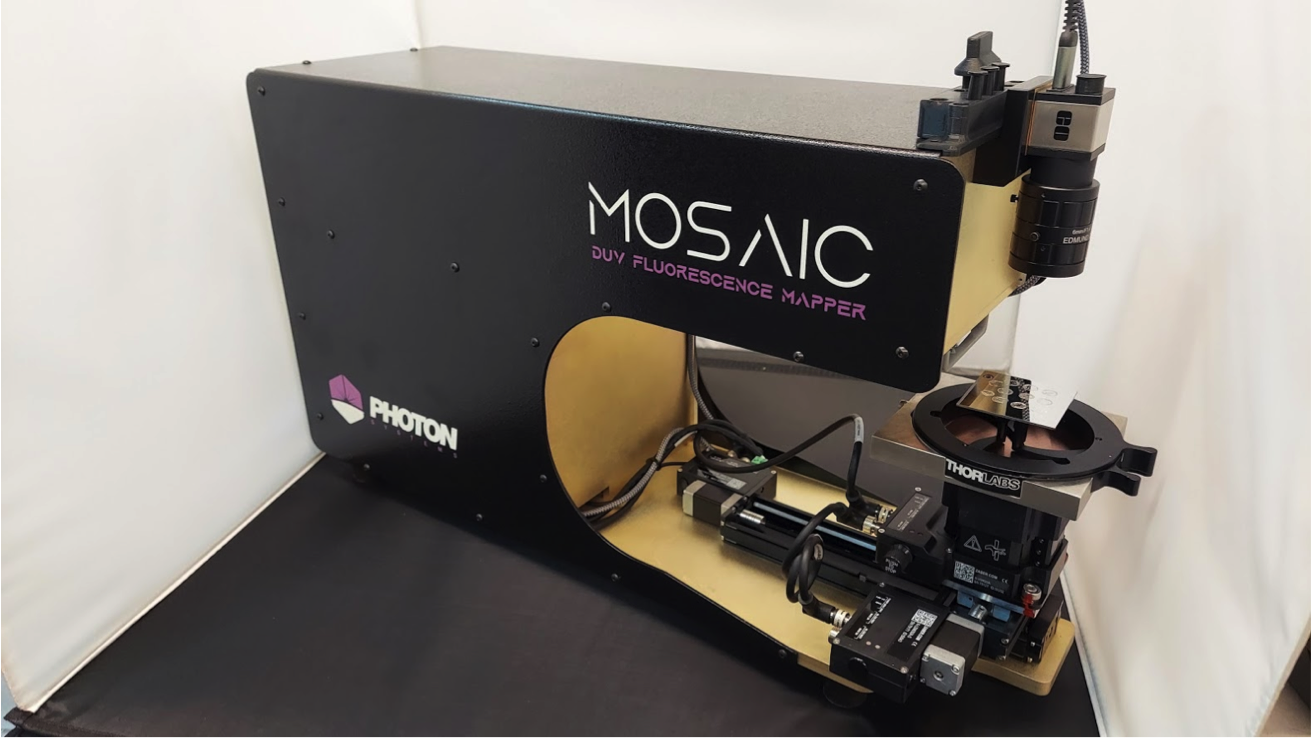

Detecting and quantifying trace surface contamination is an important step in many manufacturing processes. Organic compounds such as oil, grease, cleaning agents may be present on surfaces in low concentrations. This needs to be detected before a sensitive processing step such as bonding, coating or welding. Or, the final cleaning may need to be verified before an item is delivered to customers.

Other technologies used for trace surface contamination detection may include total organic carbon, optical imaging, FTIR, optical emission spectroscopy, reflectance hyperspectral imaging and solvent extraction/swabbing. All of these techniques have limitations such as lack of sensitivity or signal response, operator training issues, inability to work on curved surfaces, limitations on material types or not feasible for in-line processes.

Deep UV fluorescence detection offers significant advantages for organic trace surface contamination detection. With laser based detection, the limit of detection can be well under 1 nanogram per square cm and the working distance can be up to 1m. This can allow the surface contamination detection on parts with unusual shapes. The detection is real time and can be quantified through the generation of calibration samples (using the ChemCal) and fluorescence response calibration curves. Therefore, the deep UV fluorescence signal is correlated to a known contamination concentration. Also, through the use of multiple detection bands, multiple contaminants can be detected.

Key Issues

Low Limit of Detection

With laser based deep UV fluorescence detection, the threshold for detection is under 1 nanogram per square cm.

Stand Off Detection

Detect surface contamination up to 1 meter away with high sensitivity

Detect on Irregular Surfaces

All shapes, contours and textures can be analyzed

Calibrated Detection

Deep UV fluorescence detection calibration curves can be generated with calibrated test samples to enable quantitative measurement of surface contamination

Downloads

ChemCal

A trace chemical detector like the TraC or TUCS 1000 is acceptable for many applications only if you can accurately calibrate its performance and generate reproducible chemical concentration curves. That is why we created the ChemCal.

Get In Touch

Keep informed about the latest deep UV developments at Photon Systems by joining our mailing list.

ADDRESS

1512 Industrial Park St. Covina, CA 91722-3417

PHONE

626 967-6431